The use of natural gas-fired generation in Ontario is increasing, and the trend will continue for several years. Growing demand for electricity, and the loss of nuclear capacity with units down for refurbishment, means natural gas units are increasingly called on to provide power, even in off-peak hours. The increased use of gas generators is reflected in the behaviour of Hourly Ontario Energy Prices, especially impactful on larger, Class A electricity users. But the trend also has significant consequences for those looking to reduce greenhouse gas emissions through electrification.

Natural gas-fired generation sits near the top of Ontario’s generation stack. Resources like nuclear power, hydro, wind, and solar have lower marginal operating costs, and so they tend to be dispatched first. These sources are also considered “non-emitting” from a GHG perspective. Gas generation is mostly called on when the grid’s needs cannot be satisfied by these other sources.

Ontario is in the midst of a multi-year project to refurbish and extend the useful life of nuclear generators at Bruce and Darlington. With as many as 3 or 4 nuclear units offline at a time for refurbishment, Ontario’s nuclear capacity is reduced by 2500-3000 MW. That means gas generation is called into service more often, to take up the slack. The refurbishment program is expected to continue to 2033. Meanwhile, Ontario’s oldest nuclear generator at Pickering is expected to shut down its 6 remaining units by 2026, removing another 3100 MW of non-emitting capacity. The situation is exacerbated by demand in Ontario growing at a rate of about 2% a year, in part due to increasing electrification.

When natural gas-fired generation must run to meet the current demand on the grid, we say that gas-fired generation is the marginal source of supply, or it is “on the margin”. That means that the next increment in demand will be satisfied by an increase in gas-fired generation. This condition used to prevail in Ontario mostly during periods of peak demand, on hot summer days or cold winter evenings. But increasingly, the situation exists even in off-peak periods, such as overnight hours or during spring and fall.

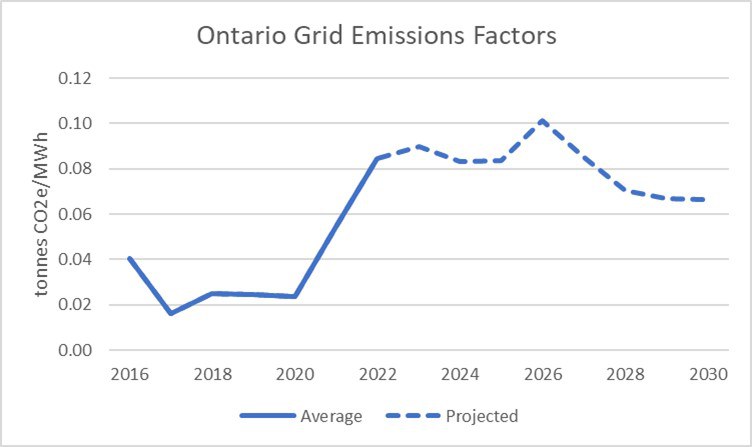

The increased use of gas-fired generation is reflected in the emissions factor of Ontario’s grid. The emissions factor is the average tonnes of CO2 emitted per MWh of electricity generated on the grid over the year. It is derived simply by dividing the year’s total tonnes of emissions by the year’s total MWh of grid generation. The emissions factor rises with increased gas generation. The trend in emissions factor is shown below.

The average grid emissions factor is used by energy consumers to assess their Scope 2 greenhouse gas emissions, which include emissions associated with the grid electricity they have used. A consumer that replaces on-site natural gas use with electricity -- for example, by turning off a cogenerator or replacing a gas-fired boiler with an electric one – will see their direct Scope 1 emissions fall, and their Scope 2 emissions increase. But because the Ontario grid has a lot of non-emitting generation and a favourable emissions factor, the net effect is a reduction in the calculated total (Scope 1 + Scope 2) on-site emissions.

Under the carbon pricing regime in effect in Ontario, consumers pay carbon compliance costs on their Scope 1 emissions (for large emitters) or a fuel carbon charge on the natural gas they buy. Either way, they are incentivized to reduce gas use and lower Scope 1 emissions. This is the motivation for decarbonization through electrification.

But let’s consider what is happening when an Ontario consumer electrifies their gas demand.

If a consumer turns off their gas-fired boiler and turns on an electric one, or turns off their cogenerator and buys electricity instead, when gas-fired generation is on the margin, then the incremental electricity needed on-site will come from gas-fired generation on the grid, since all the non-emitting sources are already at capacity. So natural gas is still being consumed to meet that energy demand, but instead of being consumed in the on-site boiler, it is being consumed in a generating station somewhere on the grid.

To the consumer, the effect is unseen. The consumer will have reduced their gas use and Scope 1 emissions, lowering their emissions compliance cost and reducing the total emissions they report for their operation. The increased gas use on the grid will nudge up the average emissions factor reported at the end of the year that the consumer (and all other consumers) uses to assess their Scope 2 emissions.

But have overall emissions really been reduced? In fact, they may have gone up.

Even the most efficient gas-fired generators on the grid are less efficient than the equipment typically used on site to turn gas into thermal energy. This means that, if on-site boilers are converted to electricity and gas-fired grid generation provides that electricity, more gas is used – and more emissions created – than before.

It is noteworthy that the use of high efficiency equipment like heat pumps can overcome this problem. Heat pumps can operate with efficiencies of 300-500%, and since they use much less electricity to produce the same thermal output, the emissions from gas-fired generation to power a heat pump would much lower than those from the gas-fired boiler or cogenerator it replaced.

An operator with both a gas boiler and an electric boiler can reduce overall emissions effectively by running their gas boiler when gas-fired generation is on the margin and running their electric boiler in the remaining times. However, the average operator may find it challenging to monitor grid operations continuously to be able to make this call. And importantly, when the operator is using their gas boiler to lower Ontario’s overall emissions, they are increasing their own Scope 1 emissions and may be increasing their carbon emissions compliance costs.

As policy initiatives driving us toward a “clean” grid take hold, then eventually the electrification of energy demand will result in lower overall emissions, even for lower efficiency applications like boilers. In the meantime, operators may need to consider more nuanced operating strategies or more efficient technologies if the beneficial emissions reductions they expect from their electrification investments are to be realized.

-

Electrify your operations to reduce GHG emissions? Perhaps not that simple.

On Ontario's electricity grid, natural gas generating units are increasingly called on to provide power, even in off-peak hours. The trend has significant implications for those looking to reduce greenhouse gas emissions through electrification.

read more -

Generational change: Experienced senior staff are leaving

Many organizations face a growing challenge as senior employees leave the organization, taking with them significant knowledge and experience. Outsourcing expertise can be an effective way to fill the knowledge gap quickly, while lowering costs and reducing risks.

read more -

Electricity price behaviour in Ontario is changing

Increased reliance on gas-fired generation will lift hourly electricity prices in Ontario. Higher HOEP and greater demand will lower Global Adjustment costs. It's a dynamic Ontario consumers have not seen in a long time.

read more